François De Bellefon - Customer Success Manager

To remain efficient, manufacturers need a corrective maintenance system that has a minimal impact on production. However, one of the key issues before the repair stage is to accurately and quickly identify the cause of the breakdown in order to provide a solution.

Factories that operate 24/7 or at high production rates can be particularly affected by surprise failures, thus degrading the availability of their production asset. If they are not anticipated by preventive maintenance operations, some breakdowns can bring an entire workshop to a standstill for several days, resulting in significant costs. The experience of the maintenance technician plays a decisive role in the resolution of these incidents, as it significantly reduces the time needed to diagnose the incidents and repair the parts concerned. In reality, the plant’s maintenance technicians are not always present or available when a production problem occurs. In addition, many manufacturers are struggling to maintain the knowledge of their experts and to recruit new ones. Operators and line managers are thus in the front line to try to resolve the situation.

While various types of incidents can cause machines to break down, it is sometimes necessary to call on the expertise of maintenance teams to make a diagnosis. If no solution is found internally, it is necessary to call on the equipment manufacturer or a maintainer to intervene, either remotely or on site. This intervention imposes an additional delay for the repair, even more so if it takes place in a foreign factory. So how can we improve the autonomy of operators so that they can diagnose or resolve an unexpected incident without resorting to third-party assistance?

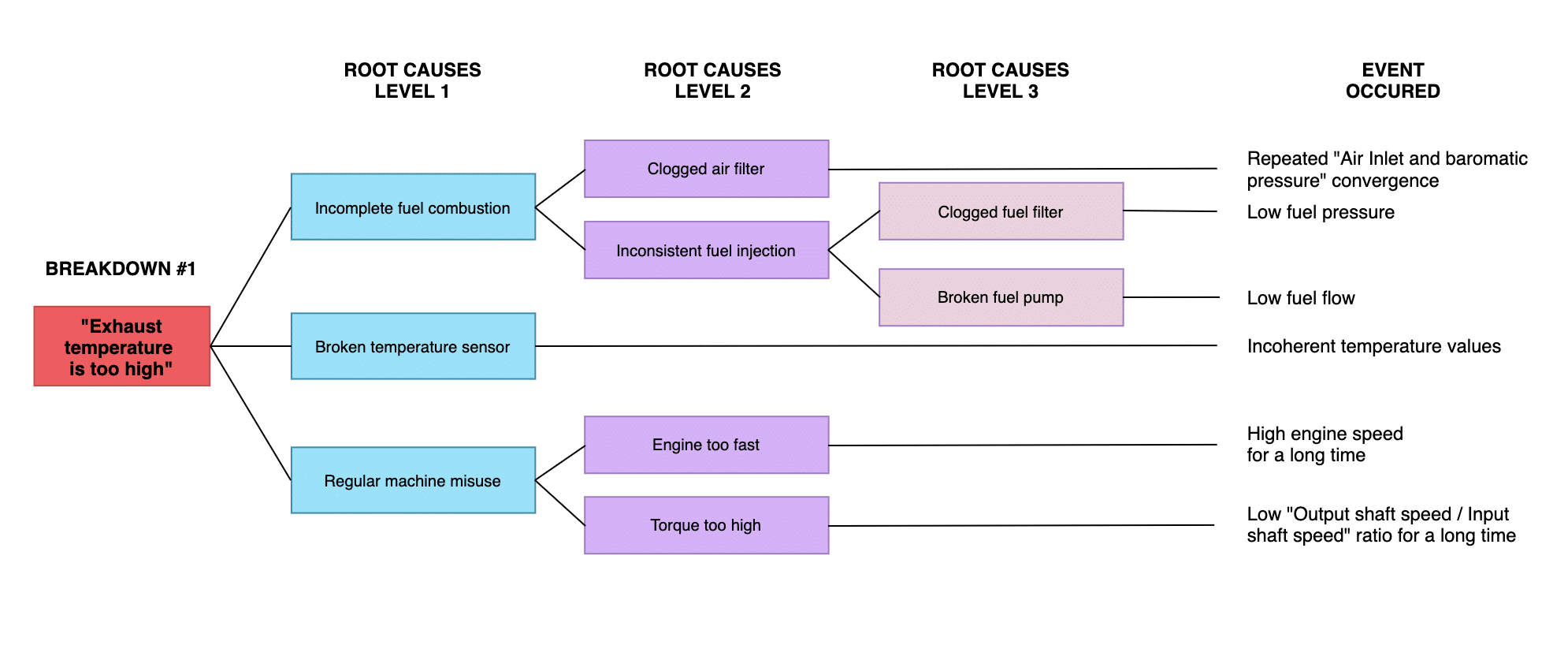

Root Cause Analysis (RCA) tree example

If a traditional CMMS solution allows to efficiently follow the progress and scheduling of maintenance operations carried out after the fact, it offers only limited assistance to help operators deal more efficiently with this type of incident. Conversely, a connected solution can accelerate the execution of corrective maintenance procedures by helping the teams in the field as soon as the breakdown appears.

The implementation of a connected corrective maintenance solution is based first of all on a phase of expression of the problems encountered, which account for the defects of the machines (impact, periodicity, prior signals, etc.). This work, carried out in collaboration with the manufacturer’s maintenance experts, allows the definition of a digital repository of failures.

In a first step, the most critical breakdowns are listed according to the field experience or the available recorded data (e.g. distribution of declared incidents). In a second step, their behavior is analyzed according to the “root cause” method (also called “5 whys” method). The consolidation of this collective intelligence allows the dissemination of proven resolution methods directly in the field and provides additional skills to the maintenance team members, so that they can restore equipment more quickly.

As an example, root cause analysis is successfully applied to the case of technical failures of mobile industrial machinery such as bulldozers. The issue is important when these machines are used in the context of a mine for instance, and therefore far from the assistance teams in case of failure.

In this case study, the causes of each known incident are broken down into a sequence of distinct scenarios. This preliminary work makes it possible to obtain a tree of relevant root causes, whose probability is weighted according to the production context. The creation of this repository allows technicians to immediately access a specific resolution framework in order to proceed with on-site inspection and repairs based on replacement procedures.

Example of automated diagnostic realized by the equipment, completed with a resolution procedure and a feedback loop for the operator

Connected solutions like InUse’s provide field teams with the results of these analyses in real time. In the event of a breakdown, the machine becomes capable of self-diagnosis by precisely recognizing the context of the incident, characterized by the previously defined chain of events. In addition, it delivers actionable operational content such as the resolution procedure and practical documentation on the affected component.

The use of this type of solution requires the prior connection of the equipment for which the data is recovered to qualify the failure behavior. In the case of the machines studied above, multiple data are collected and analyzed: error code, engine usage (engine speed and torque), atmospheric conditions (pressure, temperature), air supply (pressure, temperature), cooling system (temperature), fuel (level, flow, pressure). Exogenous data such as humidity level, periodic engine oil analysis results and the date of the last maintenance of each critical part are also taken into account.

Ultimately, it is the concomitance between the digitization of experts knowledge and production context as well as the provision of easily accessible recommendations for the teams in the field that allows faster actions. In a few seconds, operators have a self-diagnosis of the machine with an operating procedure. They are then able to confirm or not the diagnosis and, if necessary, to immediately follow the resolution procedures.

Example of curative maintenance performance dashboard

In addition, the data reported allows managers to monitor the distribution of errors, the time spent down, the average restart time (MTTR: Mean Time To Restart) and ultimately the impact on equipment availability. This information is also useful in managing maintenance teams, in order to prioritize the upgrading of skills.

Beyond the assistance provided to teams during an incident, the impact of this type of solution becomes more and more important as feedback is received from the field : diagnosis confirmed or not, additional input values found on equipment, etc. This data is a very useful source for refining models after the fact. In this context, the use of Machine Learning algorithms allows to refine the probability of each “root cause” and thus make the diagnosis from the equipment more reliable over time, in a logic of continuous improvement.

By combining cognitive and artificial intelligence, connected maintenance solutions provide operators many advantages with new assistance that allows them to intervene more frequently on their own in an easy way. This considerably reduces the time spent on diagnosing and resolving incidents. This translates into a reduction in equipment restart time and an increased level of availability and OEE (Overall Equipment Effectiveness) of the production asset. In cases where production stoppages can last for hours or even days, autonomous incident resolution allows significant productivity gains.

In workshops, the implementation of these new connected corrective maintenance solutions has a direct impact on the autonomy of teams in resolving failures. Moreover, it promotes the development of skills of teams assisted in real time by the application, but also a better use of equipment. In this perspective, equipment manufacturers have a key role to play in helping their customers make better use of their equipment on a daily basis and thus reduce the risk of breakdown over time.

Related News