Playing a major role in the industry, motors are omnipresent while being costly in maintenance and electrical consumption. Any production shutdown due to a critical motor failure in the production line turns out to be extremely costly.

Keeping an eye on motors through predictive maintenance helps to anticipate and avoid breakdowns, optimize maintenance with intervention on time (neither too early nor too late), and ensure appropriate power consumption.

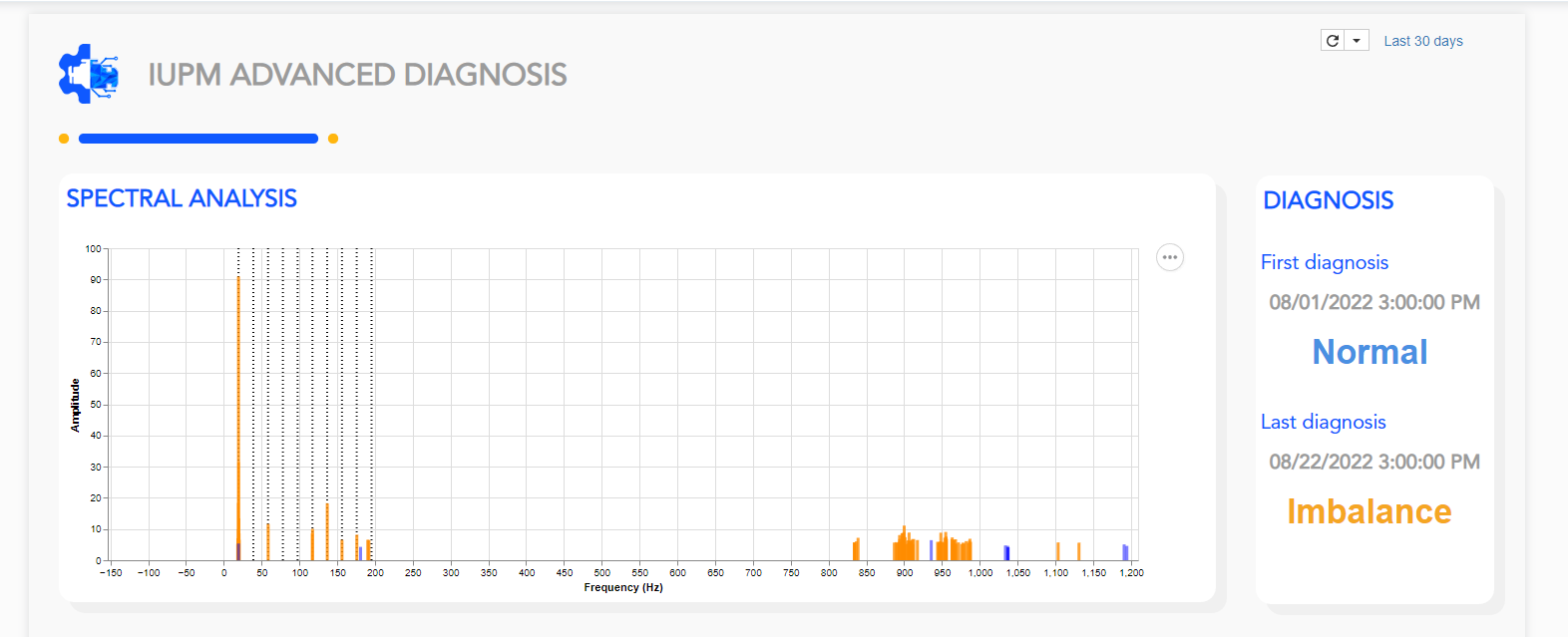

The new IU PREDICT for motors application, based on motor vibration analysis, collects data directly from the equipment and offers a turnkey interface to easily view the results : motor performance, user alert, and associated diagnostic before failure.

IU PREDICT is a packaged application, complementary to the studio and quickly implemented.

Knowing that a motor has a failure is good, knowing its origin is better! And this is what the Advanced Diagnostic level offers.