Maintenance 4.0 in industry is not limited to factories of the future. It can be introduced and adapted to your context regardless of your level of digital maturity and types of maintenance (preventive, curative, predictive).

The combination of IoT solutions and artificial intelligence paves the way for predictive maintenance thanks to the ability to anticipate breakdowns before they occur.

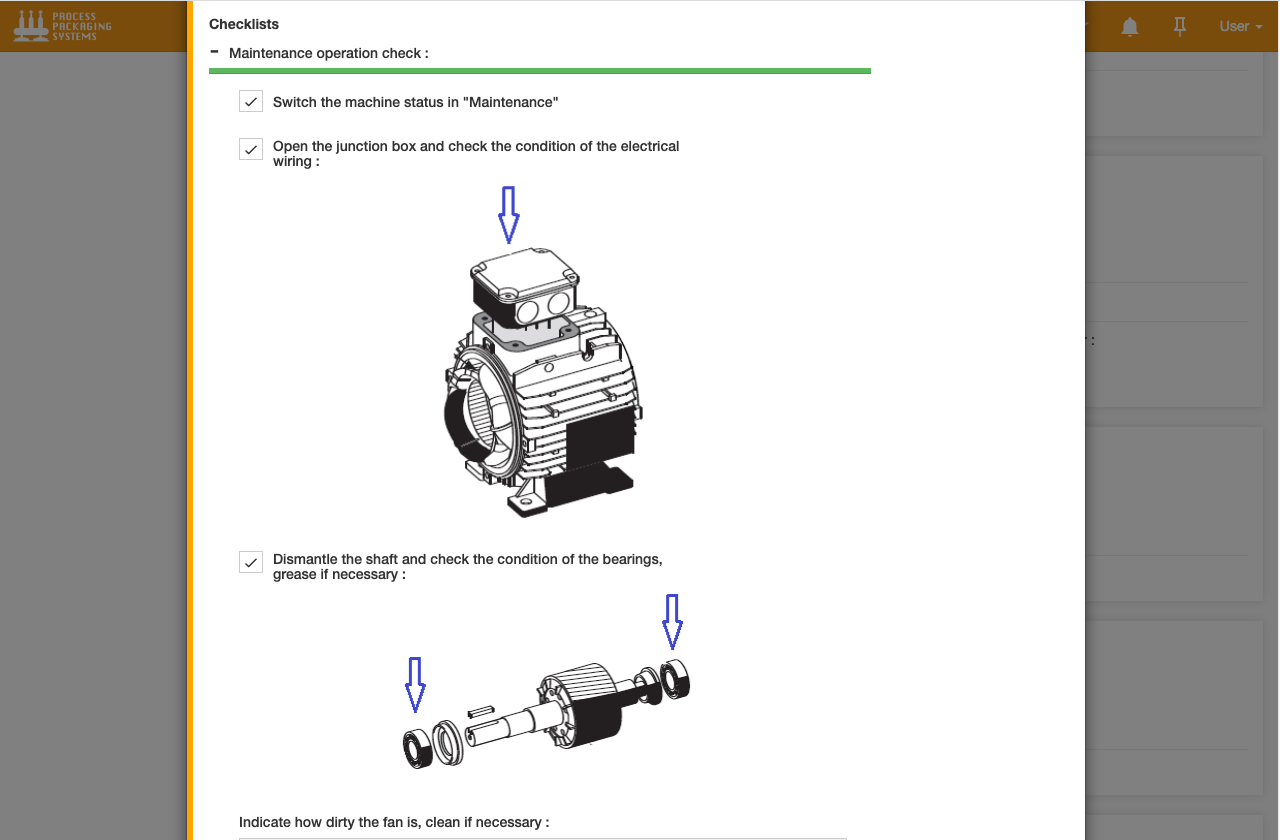

Preventive maintenance operations based on scheduled recommendations cannot ensure that equipment is maintained in optimal operating condition. Our industrial IoT platform takes these operations to the next level by taking into account actual equipment wear while also digitalizing the entire process.

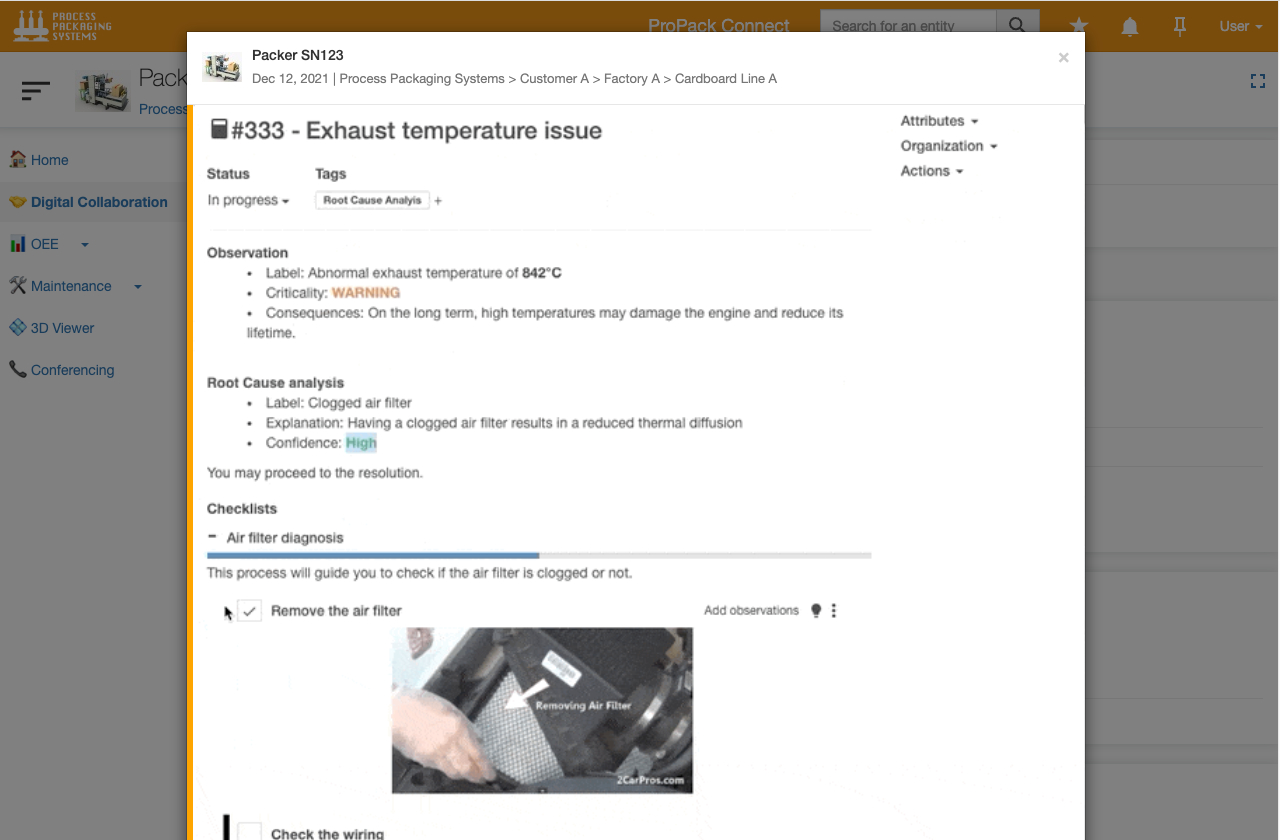

The cost of a production shutdown is considerable in industry sectors with fast-paced operations. Responsiveness is therefore key in reducing restart times for broken down equipment. The InUse platform provides a practical solution that allows maintenance operators and technicians to resolve these incidents more quickly with greater independence.