For many machine manufacturers, acceptance tests (SATs) and scheduled maintenance visits are the only time that technical teams have the opportunity to evaluate the usage and performance of deployed equipment.

Outside of these appointments, and without connectivity, this information is often subjective as it relies solely on ad hoc users statements.

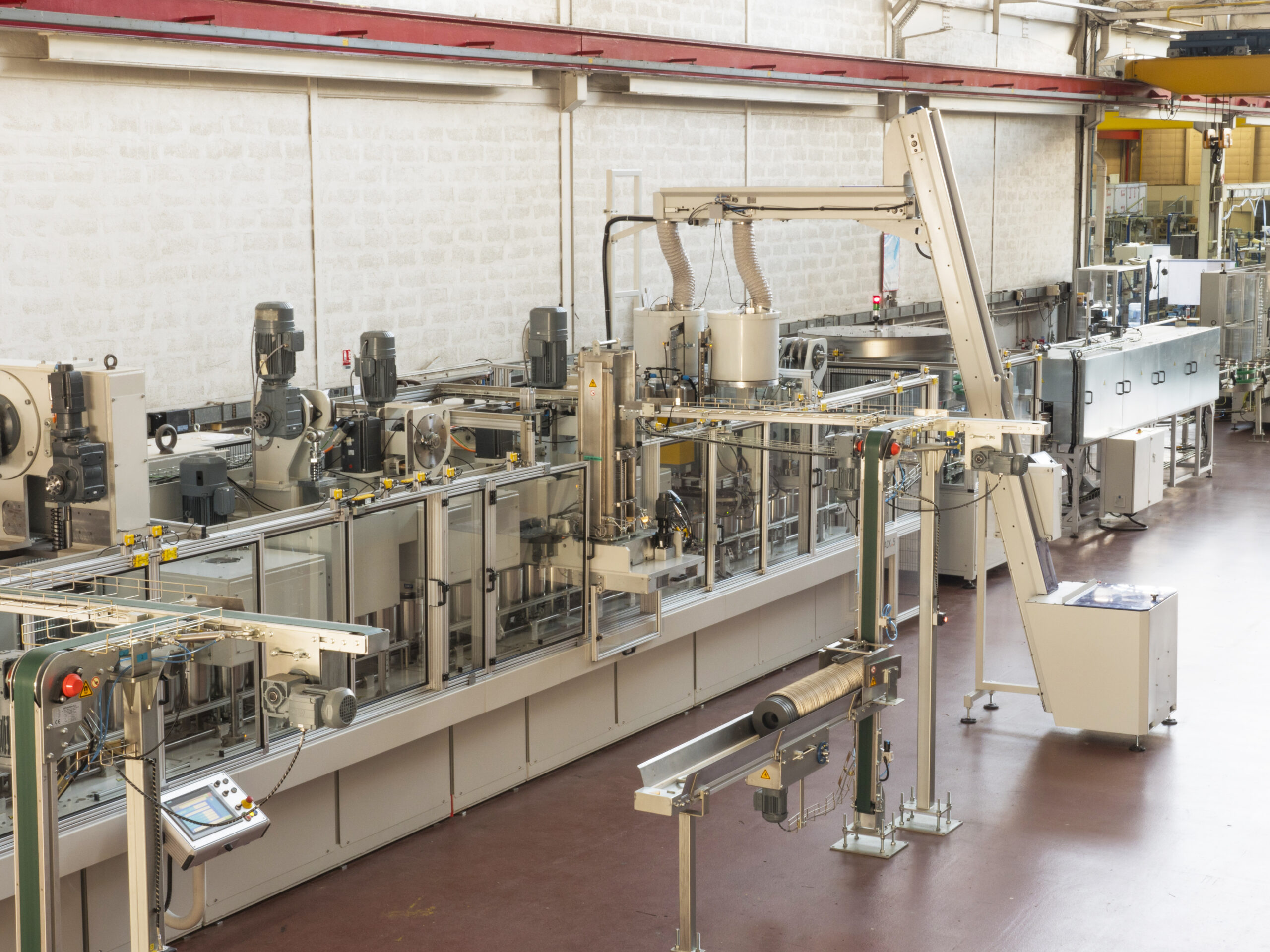

Therefore, Sabatier, a French equipment manufacturer, and leader in 3-piece metal packaging assembly equipment, sought a long-term connectivity solution to monitor its equipment and develop its service offer. Given that 90% of the company's turnover comes from exports, it quickly becomes clear that it is essential to maintain a close relationship with its customers.

9 months

to design and deploy a new connected services offer

20 %

productivity difference between connected machines

15

first connected equipment worldwide in just 3 months

Sabatier and InUse share the vision that the added value of a digital service lies in its ability to help users on the business side. However, the best knowledge of equipment is held by the machine manufacturers. Consequently, combining this field expertise with the data provided by InUse leads to a stronger added value, faster deployment and ensure end-users to get the best performance from their machine.

After several internal developments, Sabatier moved toward a turnkey solution and chose InUse MRM, with a twofold objective. Firstly, offer a complementary solution to the current supervision service used by their customers. Secondly, obtain factual data on the use of their equipment to:

After a 3-month pilot phase and a 6-month industrialization phase, Sabatier teams led by Jean-Louis Pellegatta (Head of Engineering) and Arnaud Jannin (Automation Engineer), accompanied by InUse teams, were able to design and deploy several connected performance services giving after-sales teams the means to:

Included within the warranty period of every new machine, Sabatier’s connected application is now in operation in multiple countries in Asia, Europe, and the United States.

In this perspective, Sabatier intends to enhance the application with new advanced performance services, such as automated recommendations based on the on-going recipes. They will also provide open access to their spare parts catalog and procedures to help with adjustments and maintenance. The goal is to increase existing customer loyalty and deliver an even higher level of service.

The implementation of InUse MRM solution is a great help to teams in charge of monitoring the deployed equipment.

“With the ability to manage data in real-time and detect complex sequences, InUse MRM solution helps us a lot during the production or maintenance phases and thus perfectly meets our objectives: in a few clicks we understand how our machines work, their level of productivity and the difficulties encountered.”

Didier Torrelli, CEO, Sabatier (Soudronic group)

About Sabatier :

Located in Vitrolles, near Marseille, Sabatier offers a wide range of production systems for 3-piece cylindrical, conical or irregularly shaped metal containers (drums, buckets and barrels). The company designs and produces stand-alone machines as well as custom turnkey systems.