A Cleaning-In-Place station operating according to TACT* principles cannot adapt its cleaning cycles according to the actual cleanliness of the equipment (pipes, pasteurisers, etc.).

In response to this need, InUse has developped IU SUSTAIN for CIP (Pure Cleaning).

* (Temperature – Action – Chemistry – Time)

IU SUSTAIN for CIP (Pure Cleaning) is a responsible solution combining algorithms and optical sensors to optimize the duration of Cleaning-In-Place processes without compromising their compliance. This solution is ideal for manufacturing companies seeking to improve the availability of their production lines and significantly reduce their water consumption.

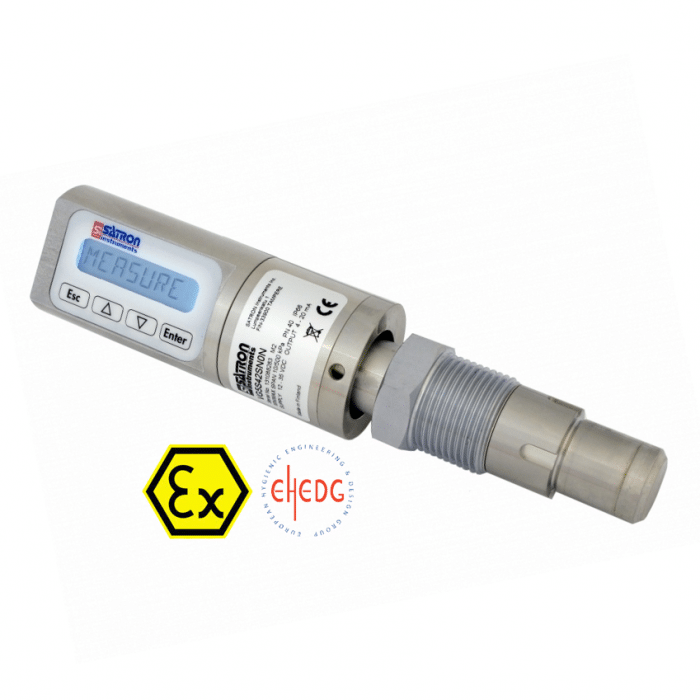

Based on a combination of Satron optical sensors and a web application, IU SUSTAIN for CIP optimises cleaning stage times for equipment without compromising their compliance with the following benefits:

Time

Greater availability of cleaning lines

Resources

Significant reductions in water consumption

Quality

Continuous quality control of CIP compliance

IU SUSTAIN for CIP (Pure Cleaning) Application by InUse

Satron Sensors by Capflow

Discover how dairy group Hellenic Dairies reduced their water consumption from cleaning in place processes by 20% in just a few months.