The increasing use of industrial IoT solutions gives manufacturers the ability to create digital representations of how their production processes work, while measuring and tracking their continuous improvement processes in a digital twin model. In addition, Artificial intelligence is making equipment capable of steering production teams towards taking better decisions. This two-pronged approach simultaneously speeds up knowledge-sharing processes in a production setting and roll-out of continuous improvement cycles, such as PDCA and DMAIC.

The digital twin model works across all connected services to help slash the amount of time, materials, and natural resources wasted in a factory via a single, unique IIoT platform accessible in SaaS mode from any web browser.

Create digital continuity for your production data: machine data (PLC, sensors..), process data (ERP, MES, SCADA, and more), and manually-input data.

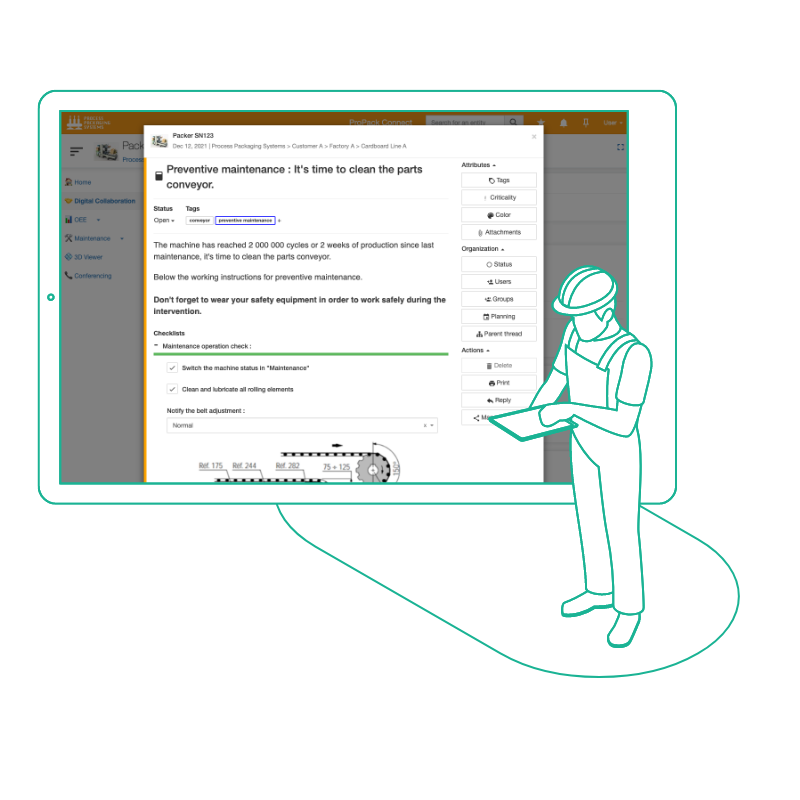

Concrete, actionable recommendations issued by your machines at exactly the right time, paired with clear diagnostics and step-by-step procedures.

Connected services that are easy to replicate across other production sites for accelerated deployment of theplatform across multiple sites.

Designed to tackle performance, maintenance and process optimisation in production sites, digital twins let you roll out a range of connected services across one or more production sites to improve performance while reducing your environmental impact.

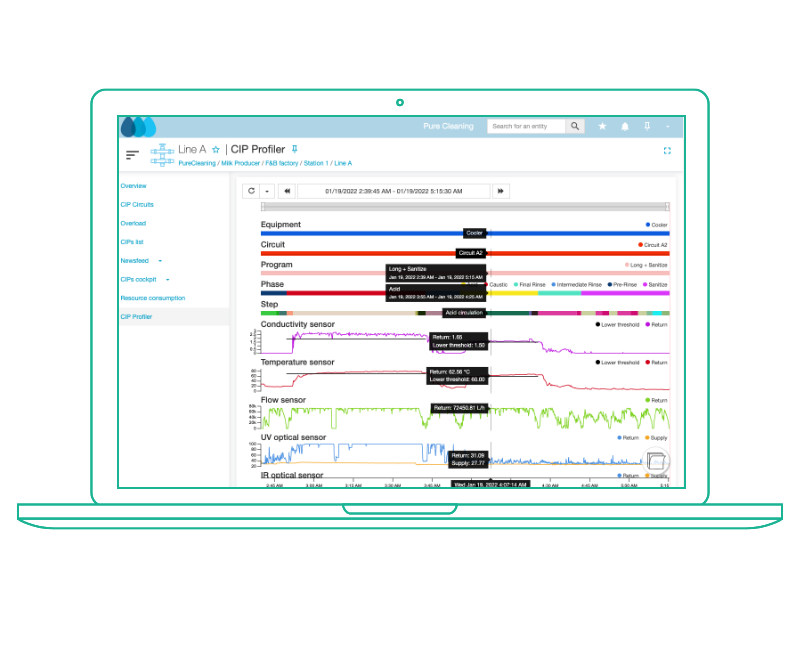

Enjoy access to an unparalleled overview of your operations and identify optimal performance conditions by analysing machine data in real time:

Better yet, InUse’s digital twin gives production sites the ability to resolve complex performance issues such as:

Understanding and preventing production shutdowns is key to production sites hitting their eco-efficiency targets in terms of heightened production line availability, waste, and reduced resource consumption.

Because of this, InUse’s digital twin offers a range of different industrial automation and IoT options to drastically improve maintenance operations in line with your goals:

Thanks to our many collaborations with process industry experts, InUse’s digital twin offers a selection of digital services dedicated to achieving continuous improvement across various key factory processes, such as:

Find out how dairy group Hellenic Dairies tapped into the advantages of IoT based industrial automation by rolling out connected services across its factories, generating significant gains in terms of performance and reduced water use.