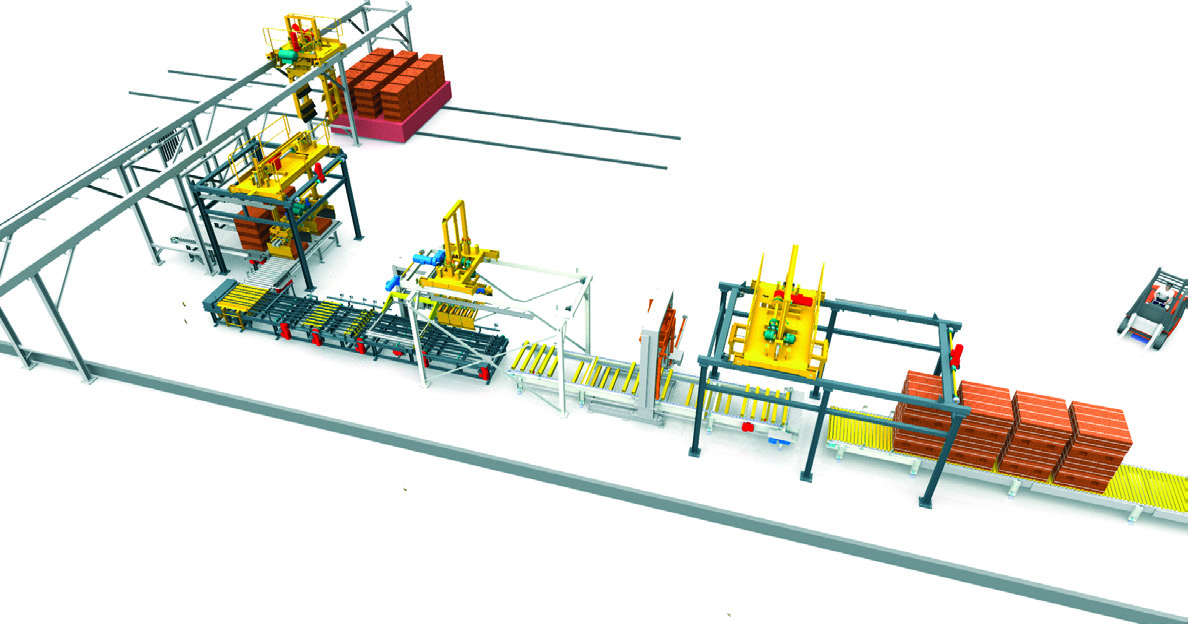

ALFI Technologies is a true pioneer in this field and has been integrating digital twin technologies in all phases of its projects for several years, thus offering optimal and accelerated support to its customers.

The creation of an animated 3D model in the pre-project phase, the simulation of the production process, as well as the emulation of the PLC backed by virtual reality control save time and guarantee security for customers, thus promoting a faster start-up in complete confidence.

Since 2017, ALFI Technologies has been extending its digital twin into the use of equipment in real conditions with the help of InUse. Objective: offer new connected services that improve performance and reduce the environmental impact of equipment.

15 to 20%

less energy consumption depending on the application

3 hours

saved per day on average by several ALFI Technologies customers to ensure performance monitoring

20%

reduction in the duration of the Site Acceptance Test

InUse's expertise combined with ALFI Technologies' production and business knowledge, has given birth to the Alfi inUse IoT platform, which includes various connected services dedicated to the performance of equipment and their maintenance :

Easier exchanges and faster decision-making

Beyond the services deployed, the platform greatly facilitates interactions between ALFI Technologies and its customers. Information and communications are centralized, and operators have access to documentation, instructions, and operational assistance sheets, facilitating exchanges between operators and ALFI Technologies' after-sales service.

Furthermore, the various services offered help ALFI Technologies' customers to move towards a more learning organization. Teams are more autonomous and informed, thus reducing the time required for control and decision-making in the management chain. A strategy of continuous improvement and innovation is implemented, fed by feedback from the field.

In addition to its collaboration with InUse and in order to make the most of the possibilities offered by the platform, ALFI Technologies has joined forces with CETIM and the Compiègne University of Technology (UTC) in a consortium aiming to develop advanced prediction and consumption monitoring services for curing ovens.

Beyond improving line profitability and reducing downtime, these new services offer concrete levers to oven operators to :

"We share a common purpose with InUse: to create smart, connected, environmentally friendly factories that improve working conditions and help develop the competitiveness of our industrial customers. Their platform is an essential lever for us to achieve this goal."

Yann Jaubert, Président, ALFI Technologies

About ALFI Technologies :

ALFI Technologies, a French SME, focuses on two main activities: the design, manufacture and installation of construction material manufacturing lines and the management of intralogistics equipment. The company's expertise is internationally recognized with equipment deployed in more than 50 countries around the world.