Fabrice Cadiou - Head of Customer Success

Cleaning in place: a key process that is often under-optimised

In process industry, Cleaning In Place is often carried out automatically by cleaning stations directly integrated into the production lines. The cleaning cycles then bring the production line to a standstill. Solutions are available to adjust their duration and thus increase equipment uptime while reducing water consumption.

Cleaning-In-Place is one of the mandatory constraints in the production cycle of the so-called process industries. Hygiene standards require the disinfection of production line equipment after each batch has been produced. This is the case for many sectors, particularly in the dairy, beverage, life sciences and chemical industries. These cleaning operations alternate with production cycles and constitute as many interruptions that penalise the availability of production lines.

Cleaning systems regularly disinfect the entire production lines. They consist of stainless steel tanks, storage tanks, pumps, valves and piping and integrate connections with the production equipment. In a medium-sized factory, the cleaning stations wash up to 250 pieces of equipment per day to avoid contamination from one batch to another (by bacteria or micro-organisms).

Usually, 5 steps follow each other in a complete cleaning and disinfection cycle:

a pre-rinse with hot water diffused by high flow nozzles that removes, for example, food or solids residues

a first pass of cleaning products to remove deposits and particles in the piping system

an intermediate rinse with water to remove these cleaning products

a second pass of detergent product to completely eliminate the last micro-organisms

a final rinse with clear water by a pump system

Some CIP cycles consist of 3 steps only.

Cleaning In Place is carried out according to the different principles of TACT :

Temperature: The programming defines a minimum and a maximum temperature of the liquids (water or water with added cleaning products or detergents). A minimum temperature level is expected

Action: The mechanical action of the wash depends on the flows, characterised by the flow rate and the resulting pressure. The use of spray balls enhances the efficiency

Chemistry: The use of cleaning products such as soda or caustic acid is required to dissolve organic and mineral matter. Dosages and detergent concentration are quantified

Time: The minimum time expected for each of the three previous criteria is quantified beforehand according to the washing phase

When the equipment is being cleaned, disinfected or sterilised, it is not in a position to produce. CIP thus has a direct impact on the uptime rate of production lines. Furthermore, CIPs require large volumes of water, the scarcity of which is becoming increasingly critical looking at the needs of a factory estimated at several tens of thousands of cubic meters per year. Optimising CIPs is therefore an essential lever for any manufacturer who aims to increase the availability of production lines while significantly reducing its water consumption, in other words to achieve eco-efficiency.

Inefficient cleaning phases are highlighted in blue, while other process anomalies can also be detected

Cleaning-in-place is carried out according to programmes previously defined by the objects that are the most difficult to clean. The disinfection work takes into account a reference system which is higher than the average of the cases actually encountered. In other words, as a precautionary measure, CIPs are based on the high variables of the criteria relating to TACT and hygiene standards.

However, depending on the type of residues to be cleaned, the time required to carry out certain phases of these CIPs can be reduced without compromising their compliance, by eliminating any risk of contamination. One challenge is clear: how to optimise the duration of the cleaning process while guaranteeing the expected level of cleanliness?

Washing stations are generally devoid of sensors to evaluate the actual level of cleaning observed in equipment and piping (pipes, fittings, tank, etc.). The installation of optical sensors at the entrance and exit of the washing line is a safe and effective way to collect objective data on what actually happens during CIPs.

The combination of ultraviolet UV and infrared technologies accurately measures the level of organic and mineral residues present in the installations. The absence of observed residues ensures that the current phase can in fact be stopped without risk.

While optical sensors measure the level of fluid cleanliness at a given time, adjusting the duration of the cleaning programmes is a decision that requires the collection of a greater volume of data in order to determine a typical profile for each cleaning phase.

In this context, the systematic and continuous collection of CIP data from the station’s PLC (temperature, conductivity, flow rate, current phase, etc.) and also from optical sensors is essential. All this information feeds the basis of this optimisation process, for a low volume of data in the end.

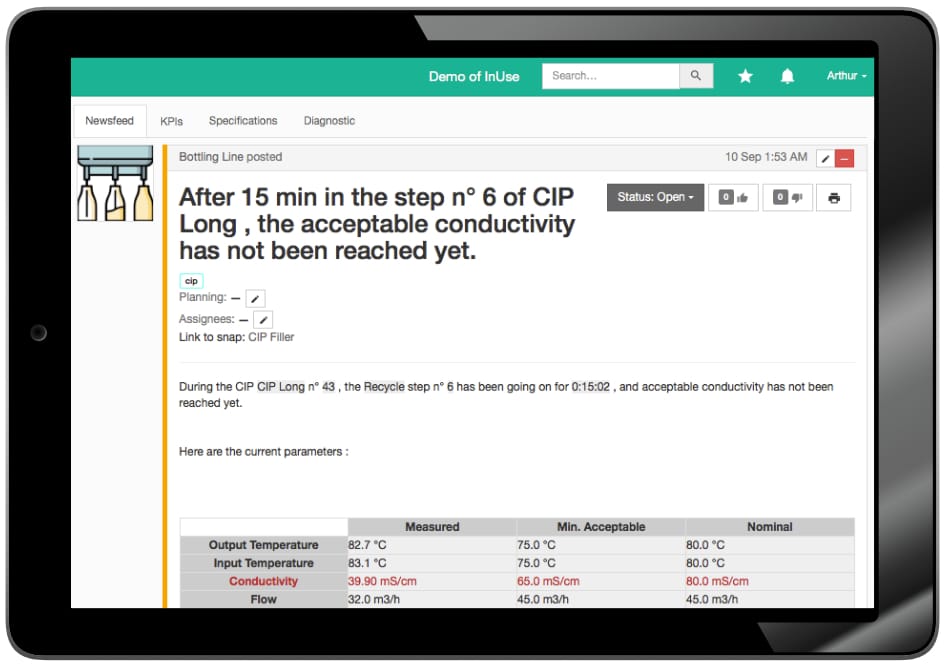

Non-compliance alert example during a CIP cycle

The link between CIPs collected data and the compliance rules laid down by each plant initially allows the implementation of a system that alerts in the event of non-compliance of cleaning and hygiene standards. These alerts also provide an initial eco-efficiency lever for the plants, by making it possible to identify possible mechanical drifts in the cleaning equipment in real time (e.g. too slow temperature rise, erratic variations in flow rate, etc.) and thus guide the production teams towards the necessary corrective actions.

While each equipment in the plant generally benefits from two distinct washing programmes (short and long), comprising between 3 and 5 distinct phases, there can thus be up to several hundred different CIP phases that can potentially be optimised within a plant. In this context, manually calculating these potential optimisations is counterproductive in terms of the time required to achieve them.

The underlying data challenge is the automation of the whole collection and analysis process so that the system can automatically provide accurate recommendations on the optimal duration of each phase.

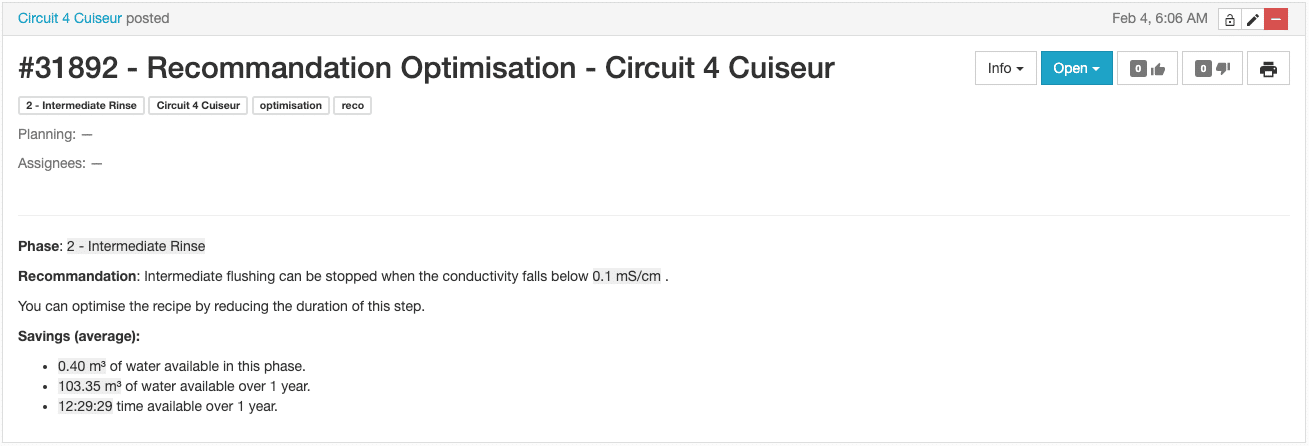

Recommendation example

Solution like Pure Cleaning automates this analysis process and provide CIP experts in the plants with the information they need to safely optimise cleaning times. The optimisation process involves the following steps:

Although CIP is an ancillary process to the plant’s production, optimising it has a real impact on its performance. By reducing the time spent on cleaning, which can be up to several hundred hours per year per cleaning line, production lines gain in availability and can therefore produce more.

In addition, the water and electricity consumption induced by these new cleaning protocols is significantly reduced. The gains observed per line and per year are on average equivalent to the volume of water contained in an Olympic swimming pool (i.e. approximately 3,000 m3 of water), which can represent between 10 and 20% less water used for this type of process.

Related News