Jérôme Alperovitch - CTO

Industry 4.0 is notably based on the principle of intercommunication between all the components of an industrial ecosystem. IoT solutions connect new machine components to this ecosystem, thus enriching the volume of exploitable data. The purpose of the InUse solution is to optimize the use of all this data. It has been designed to easily create gateways, to automatically retrieve data or to provide elements that can be easily used by other software used daily by manufacturers, their employees, suppliers or partners.

The information systems of manufacturers who use the InUse solution already have numerous applications containing precise data on the entire production system. A fundamental step in this deployment is therefore the recovery of this information, so that it can then be cross-referenced with the data from the machines connected beforehand. Synchronization of this data with the InUse platform can be achieved through the use of APIs provided to the customer, allowing for automated data transfer in an authenticated and secure manner.

To take just one example, the customer's ERP system contains all the machine nomenclature, serial numbers, model types, etc. This data is essential particularly for declaring all the machines in a fleet on the platform. When an equipment manufacturer uses InUse for all of its machines installed at its customers' sites around the world, automating this task is a considerable time saver. Thanks to the flows enabled by the API, it is possible to retrieve all the necessary and relevant data to exploit the full potential of the InUse platform, regardless of its source.

Beyond external repositories, most machines have a lot of data available about their operation. The MQTT protocol is an industry standard for machine data communication. Its use will allow the InUse platform to retrieve the various variables necessary for the implementation of the connected services to be deployed.

Similarly, the open source Node Red software will also facilitate the retrieval of data from multiple sources, both machine and database. Installed on an industrial PC on site, this application goes further than the simple transmission allowed by the MQTT protocol for example, by linking together different data sources and aggregating the desired data before transmitting it to the InUse platform.

All the data collected to feed the InUse platform will be transformed by algorithms in order to offer users connected services to better use their machines, make better decisions to improve performance or optimize energy consumption.

Within the platform, this new data can be displayed in various forms, such as alerts, notifications, reports, dashboards, time series, or synoptic views.

Two ways to leverage data created within the platform into third-party applications

This new information produced by the InUse platform will be easily made available to the client using the same flow tools but in reverse.

For the simplest data flows, InUse will in turn provide the client with its API library, allowing them to program data retrieval requests. In order to limit the number of requests, the InUse platform can also automatically push certain identified data with the use of Webhooks, conditional on the triggering of an event within the platform.

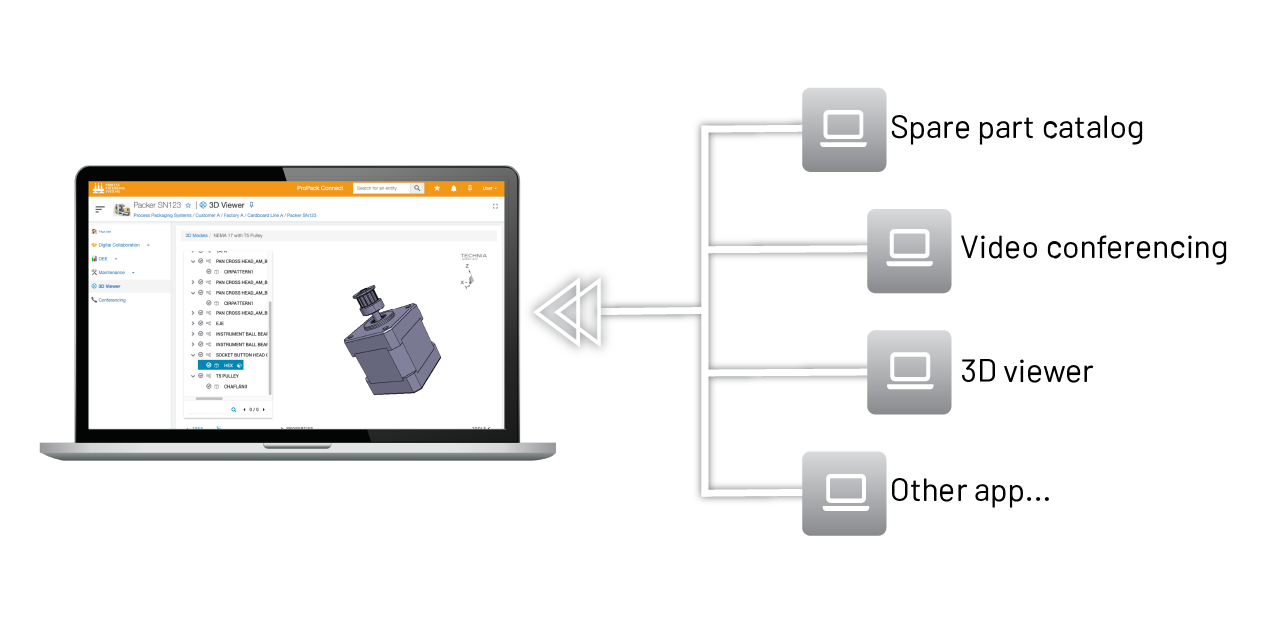

Access third-party applications directly from InUse platform

Examples of uses include :

Other more adapted methods can be used depending on the use case. For example, the application acts as an MQTT broker to allow machines to take advantage of certain data produced by the platform, thus giving them additional intelligence beyond the error codes from the supervision or HMIs. The feedback of this data to a machine, for example, takes the form of a visual alert highlighted via the light column.

In an era of increasing applications for users, their convergence in a centralized environment is a key efficiency factor. That’s why, the InUse platform now allows access to various third-party applications from the Web App, which are integrated via dedicated iFrame. Access is secured via a single sign-on (SSO) system. For example, equipment manufacturers can offer access to their spare parts catalog or 3D visualizations of their equipment. With our partner XpertEye, we have also been able to integrate their assisted reality features into our platform.

We have outlined here some of the most common ways in which the InUse platform interacts with the IT ecosystems of both manufacturers and equipment suppliers. The entire InUse structure has been designed to be adaptable and flexible, in order to offer tailor-made solutions to meet our customers' specific needs. This philosophy of integration and openness also allows us to evolve more quickly, to always have the ability to integrate new features and to take advantage of emerging technologies.

à lire également